As industrial devices have to survive exposure to harsh environments, conformal coating improves product ruggedness when applied on the module surface area. It enhances product reliability and safeguards against damage from dust, high humidity, salt water air, solvents, chemicals and other harsh materials.

Why Conformal Coating?

Conformal coating is a specialty polymeric film that protects printed circuit boards (PCBs) and electronic components from adverse environmental conditions, such as humidity, heat, fungus, dirt and dust, which will deteriorate performance. The use of conformal coatings is particularly important in automotive, military, aerospace, and industrial applications.

How Does It Work?

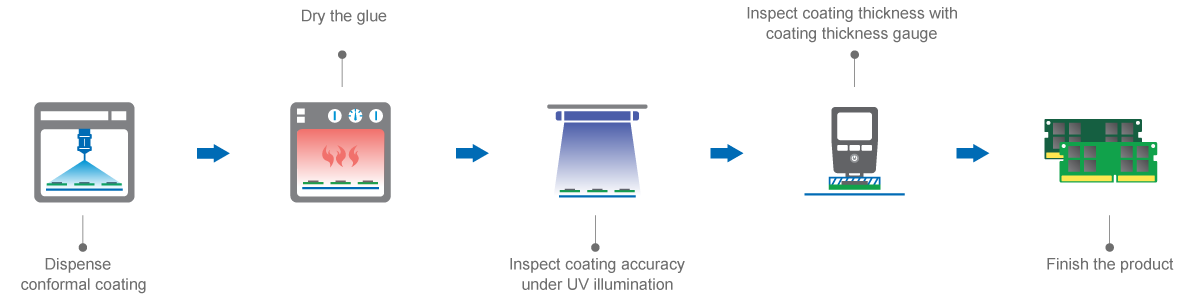

The film protects solder joints, electronic components, and other metallised areas on the board from corrosion. Once the coating type is selected, SMART's process of application is as follows.

1. Adopts automated spray systems to dispense conformal coating to the specific areas on the circuit board.

2. Dry the PCB by sending it to a curing cabinet to avoid deviation in the film's thickness and airborne particles adhering to the wet coating.

3. Inspect the still-fluorescing film with the long-wave UV lighting.

4. Measure the coating thickness to meet quality specifications which are critical in offering long-term product reliability after assembly.

5. Finish the product.